This machine is suitable for packaging cosmetics, food, olive oil, syrup, seasoning sauce, tomato sauce, honey, oral liquid oil, eye cream, fertilizers, pesticides, etc.

Fully automatic plastic ampoule molding, filling, sealing, and cutting.

Ampoule filling machines can have easy tear line production and date embossing.Features:PLC control, touch screen English operation.

PID temperature control.

The filling volume is required to be 0.5-200ml.

Power supply: According to the requirements of customers in each country.

Each machine has a CE certificate.

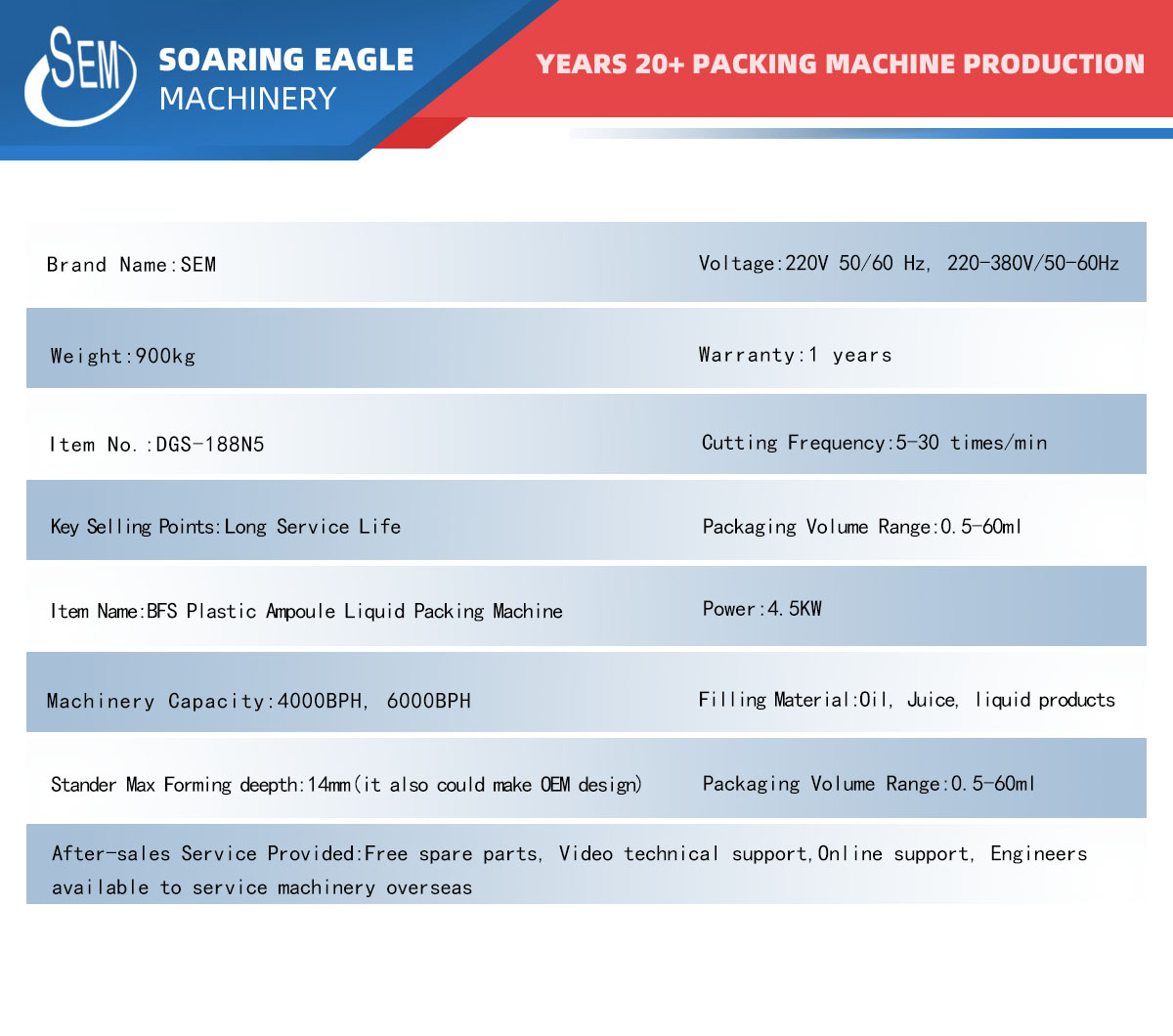

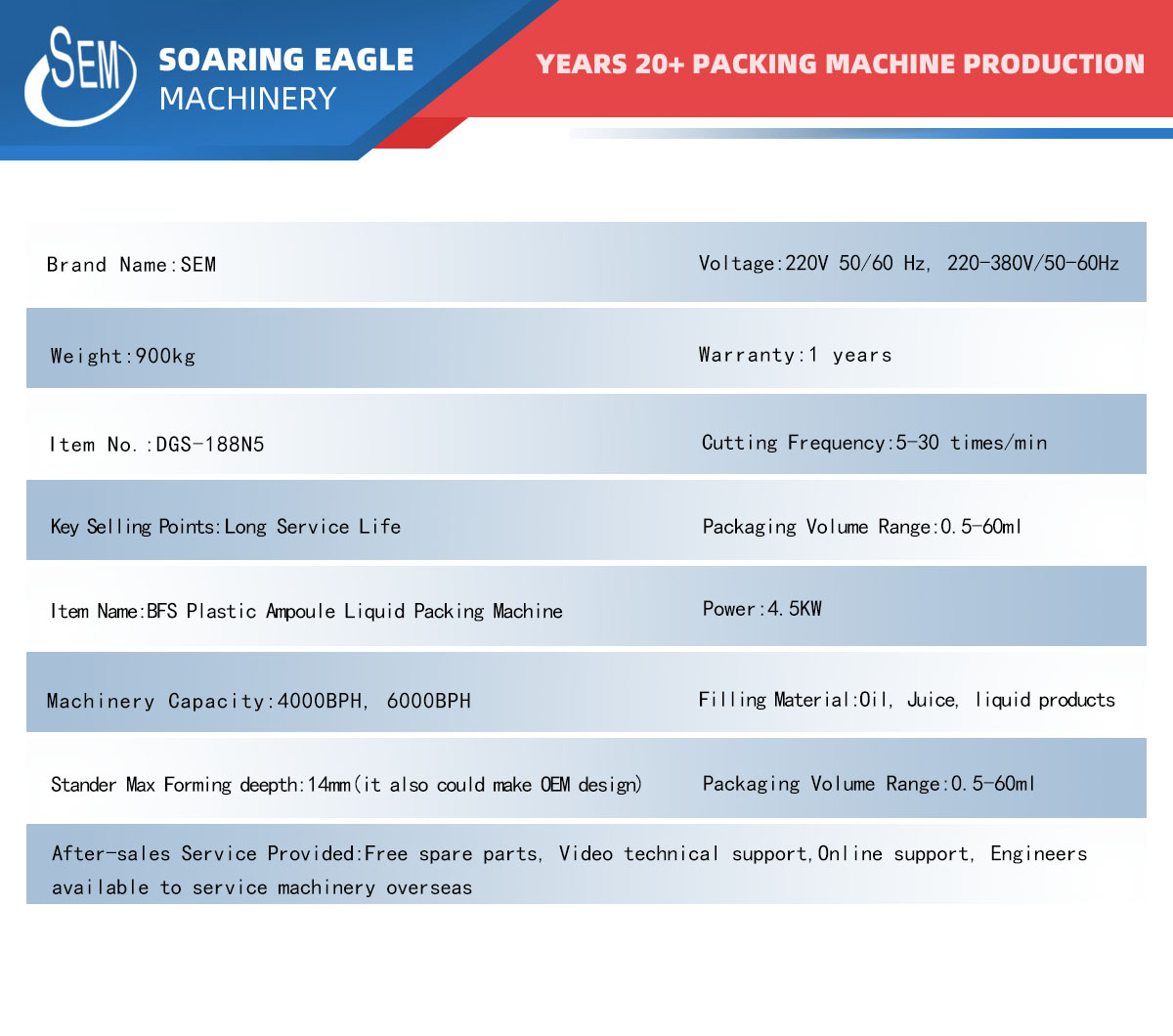

Model | DGS-188N5 |

Filling Volume | 12mm(OEM Design) |

Max Forming Depth | 1-25times/min |

Packing Material | PVC/PE.PET/PE(0.2-0.4)*240mm |

Voltage | 200ml |

Max Output | 3600pcs/h |

Powder | 4.5kw |

Automatic plastic ampoule form fill seal machine:

Machine Packaging is fit for medical , food , cosmetic product packaging such as oral liquid , chocolate cream ,jelly with soft

granule,medical gel , Aloe-gel,toner, hair dye,hand lotion,perfume and so on .

*This machine is controlled by PLC, the PLC brand could be choiced by customer, Siemens or Schneider or arranged by customer

requirements.

*This machine is controlled by PLC , the PLC brand could be selectable by customer, Siemens or Shneider or arranged according to

customer requirements.

*Stepless speed regulation,easy adjustment,running stable,save energy.

*Film spreading , ampoule forming,dosing,filling,sealing,batch No. coding,break line making,final shape cutting all total 8

working unit are finished automatically.

*Human-Machine Interface touching screen operation, easy to check the machine working data on touching screen, such as packing

speed , size etc.

*The Machine Pump will be mechanical pump or Peristaltic pump depend on different product , the filling is no drop , no bubble ,

it has suck back foundation.

*All direct contact with product parts are made of Stainless Steel 316L which is met the standard of GMP.

* Filling tolerance is ≤±1% depend on different products.

https://youtu.be/R--Yi479udo

Automatic plastic bottle forming olive oil packing machine

liquid food supplements single mono dose plastic ampoule filling sealing machine for coffee /honey

Automatic 10ml mini bottle making plastic ampoule salad dressing/ketchup olive oil lilquid forming filling sealing machine

Fully automatic food olive oil liquid plastic ampoule filling and sealing machine

Food liquid plastic ampoules, olive oil cosmetics filling and sealing machine

Automatic plastic ampoule liquid forming filling sealing machine it is the ideal packing machine for plastic ampoule, plastic vial , OEM shape product packing for liquid , cream , gel , sticky and non sticky products .

Working unit: automatic plastic ampoule forming , liquid dosing and filling , sealing with embossing for date or batch No. Cutting automatically .

Cosmetic essential oil , liquid ,food sauce , drinking products , olive oil , honey , ketchup,etc. Automatic forming filling sealing machine, according to requirements to design the product shape and size . different model machine fit for different capacity requirements .

All machines CE standard, ISO certificates with RoHS certified machines parts